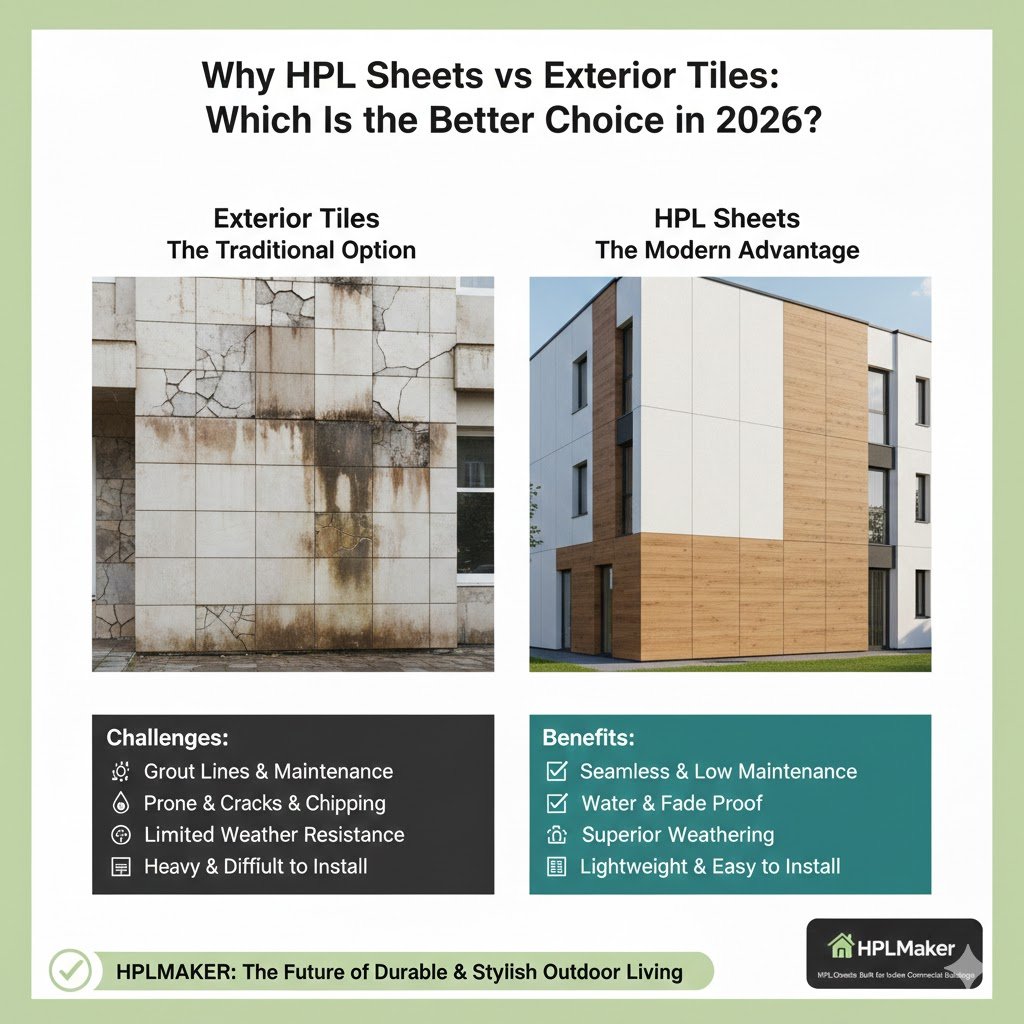

When designing modern building exteriors in 2026, homeowners and architects are increasingly comparing HPL sheets and exterior tiles. Both materials are popular, but their long-term performance and maintenance requirements differ significantly.

Let’s compare them to understand which exterior material truly delivers better value.

Understanding the Materials

What Are HPL Sheets?

HPL (High Pressure Laminate) sheets are engineered exterior panels made by compressing resin-infused kraft papers under high pressure. They are designed for durability, weather resistance, and modern aesthetics.

What Are Exterior Tiles?

Exterior tiles are ceramic or vitrified tiles used for outdoor walls. They offer a hard surface finish but depend heavily on proper installation and grouting quality.

Durability and Structural Performance

- HPL sheets are impact-resistant and handle structural movement well.

- Exterior tiles can crack or detach over time due to temperature changes and building movement.

For long-term reliability, flexibility plays a key role.

Weather Resistance and Moisture Handling

HPL sheets:

- Low water absorption

- Stable performance in rain and humidity

- No grout lines for water seepage

Exterior tiles:

- Water can seep through grout joints

- Risk of tile loosening in wet climates

This makes HPL sheets more suitable for challenging weather conditions.

Maintenance Requirements Over Time

Maintenance is a critical factor for exteriors.

HPL sheets:

- Require only basic cleaning

- Do not need repainting or regrouting

Exterior tiles:

- Require grout cleaning and repair

- May need replacement if tiles crack or fall

Lower maintenance gives HPL sheets a clear advantage.

Design Flexibility and Aesthetic Appeal

Modern exteriors demand creative freedom.

HPL sheets offer:

- Wood, stone, solid, and textured finishes

- Large, uniform panels

- Contemporary design options

Exterior tiles:

- Limited size options

- More traditional appearance

For modern architecture, HPL sheets provide greater design flexibility.

Installation Speed and Project Timelines

HPL sheet installation:

- Is faster with dry cladding systems

- Reduces on-site finishing time

Tile installation:

- Requires surface preparation, adhesive curing, and grouting

- Extends project timelines

Time efficiency favors HPL sheets.

Safety and Practical Considerations

Exterior tiles:

- Can become loose and fall if adhesive fails

HPL sheets:

- Are mechanically fixed using proper facade systems

- Provide better long-term safety when installed correctly

This is important for high-rise and public buildings.

Long-Term Cost Comparison

While exterior tiles may seem economical initially:

- Maintenance and repair costs add up over time

HPL sheets:

- Offer higher upfront value

- Deliver lower lifecycle costs

This makes HPL sheets a smarter long-term investment.

Why Modern Builders Prefer HPL Sheets

Builders and architects prefer materials that:

- Reduce post-installation issues

- Maintain appearance for years

- Support modern design trends

HPL sheets meet these expectations more consistently.

Choosing the Right Manufacturer Matters

Performance depends on material quality.

Manufacturers like HPLMaker focus on:

- Exterior-grade HPL standards

- Consistent thickness and finish

- Reliable performance over time

This ensures predictable and durable exterior results.

Final Verdict: HPL Sheets or Exterior Tiles?

In 2026:

- Exterior tiles are suitable for traditional or limited-use exteriors

- HPL sheets are ideal for modern, low-maintenance, and premium facades

For durability, aesthetics, and long-term value, HPL sheets clearly outperform exterior tiles.