As building regulations evolve, fire safety has become a non-negotiable factor in exterior material selection. In 2026, architects, developers, and authorities are paying close attention to how facade materials perform in fire-related situations.

This is where fire-resistant HPL sheets play a crucial role in modern construction.

Why Fire Safety Matters More Than Ever

Recent updates in building safety norms emphasize:

- Reduced fire spread through facades

- Use of certified exterior materials

- Compliance with local and international fire standards

Exterior materials are now evaluated not just for design, but for safety performance.

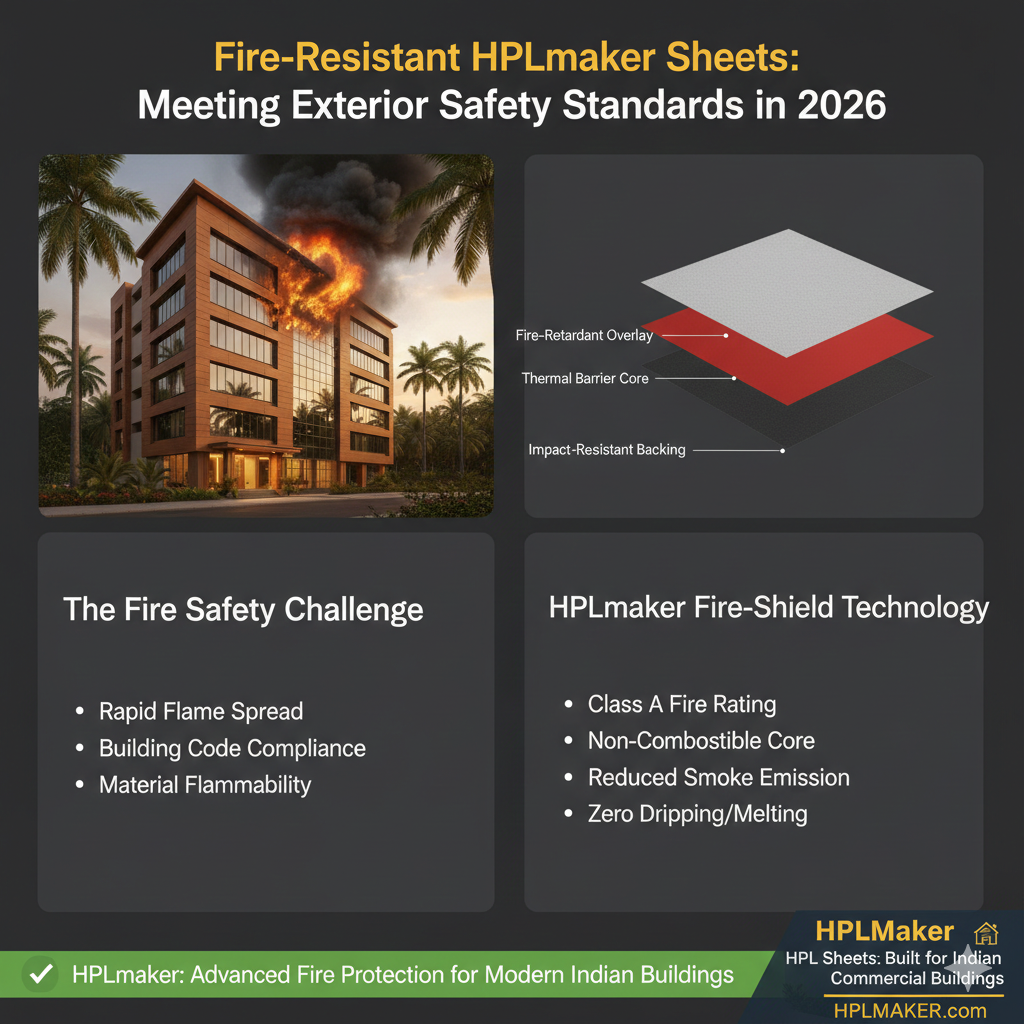

What Are Fire-Resistant HPL Sheets?

Fire-resistant HPL sheets are specially engineered laminates that:

- Use fire-retardant core materials

- Slow down flame spread

- Reduce smoke generation

They are designed to meet modern fire performance requirements without compromising aesthetics.

How Fire-Resistant HPL Sheets Improve Building Safety

Compared to standard exterior finishes, fire-resistant HPL sheets:

- Delay fire propagation on the facade

- Improve evacuation time in emergencies

- Support safer building envelope design

This makes them suitable for both residential and commercial buildings.

Compliance with 2026 Construction Standards

Fire-resistant HPL sheets are tested according to:

- Fire reaction and flame spread standards

- Smoke density and heat release parameters

When sourced from reliable manufacturers, they help projects align with updated safety regulations.

Ideal Applications for Fire-Resistant HPL Sheets

They are commonly used in:

- High-rise residential buildings

- Commercial complexes

- Hospitals and educational institutions

- Hotels and public infrastructure

These environments demand higher safety assurance.

Fire Safety Without Design Compromise

One major advantage of fire-resistant HPL sheets is that they:

- Offer the same design variety as standard HPL

- Are available in wood, solid, and textured finishes

- Maintain a premium appearance

Safety does not come at the cost of aesthetics.

Low Maintenance and Long-Term Reliability

Fire-resistant HPL sheets:

- Retain performance over time

- Do not require special fire treatments after installation

- Maintain surface quality with minimal upkeep

This ensures long-term safety and durability.

Why Quality Certification Matters

Fire performance depends heavily on material quality.

Manufacturers like HPLMaker focus on:

- Certified fire-resistant HPL grades

- Consistent manufacturing standards

- Compliance-oriented product development

This helps architects and developers meet safety approvals confidently.

Role of Fire-Resistant Materials in Sustainable Design

Fire-resistant HPL sheets:

- Extend building lifespan

- Reduce need for frequent replacement

- Support sustainable construction goals

Long-lasting, safe materials lower overall environmental impact.

Final Thoughts: Building Safer Exteriors in 2026

In modern construction, fire safety is a responsibility, not an option.

Fire-resistant HPL sheets:

- Enhance exterior safety

- Support regulatory compliance

- Maintain modern design standards

That’s why they are becoming an essential choice for safe, future-ready exteriors.